OUR LAB

INFRASTRUCTURE

OUR LAB

INFRASTRUCTURE

OUR LAB INFRASTRUCTURE

Incoming Raw Material Checks

Measure the purity and active content % of raw materials used in the acrylic polymerization process - specifically reaction catalysts and surfactants

Titration report (E-V curve) shows the purity % of an incoming catalyst used in the reaction.

Measure the purity of monomers used (like MMA, BUA) in the acrylic polymerization process

Measure the inhibitor content of monomers (e.g., Topanol in MMA) to ensure safe storage in underground tanks with minimal chance of polymerization

Measure the purity and active content % of raw materials used in the acrylic polymerization process - specifically reaction catalysts and surfactants

Titration report (E-V curve) shows the purity % of an incoming catalyst used in the reaction.

Measure the purity of monomers used (like MMA, BUA) in the acrylic polymerization process

Measure the inhibitor content of monomers (e.g., Topanol in MMA) to ensure safe storage in underground tanks with minimal chance of polymerization

In-Process Testing

Measure the amount of monomer polymerized during reaction process to ensure no residual monomer left

Measure the amount of moisture left in the spray-dried powder to ensure it is within acceptable limits

Measure the pH at seed and core stage of reaction to ensure it is within acceptable limits

Measure the viscosity of the emulsion post polymerization to ensure it within acceptable limits for pumping into spray-drier

Measure the amount of monomer polymerized during reaction process to ensure no residual monomer left

Mettler Moisture

Balance

Measure the amount of moisture left in the spray-dried powder to ensure it is within acceptable limits

Measure the pH at seed and core stage of reaction to ensure it is within acceptable limits

Anton-Paar Viscometer

Measure the viscosity of the emulsion post polymerization to ensure it within acceptable limits for pumping into spray-drier

Post Production Testing

Measure the color of the final powder to ensure that it is has the right L,a,b values that match the standard and benchmarked samples

Measure the volume of a known mass of final powder to ensure that it fits within the acceptable limits

Measure indirectly the molecular weight of processing aids using the Ubbelohde viscometer and applying the Mark-Houwink equation

Measure the transparency of the final powder in 5% toluene, as a way to ensure the PVC additive maintains transparency of final PVC product

Conduct accelerated weathering tests on impact-modified PVC to assess how additives affect the material's weatherability and mech. Properties

Measure the particle size of the acrylic emulsion at each stage of processing: from seed to core to final stage to ensure it is within 10nm of limit

Sample report of particle size to indicate D(50) value and overall distribution

Measure the color of the final powder to ensure that it is has the right L,a,b values that match the standard and benchmarked samples

Measure the volume of a known mass of final powder to ensure that it fits within the acceptable limits

Measure indirectly the molecular weight of processing aids using the Ubbelohde viscometer and applying the Mark-Houwink equation

Measure the transparency of the final powder in 5% toluene, as a way to ensure the PVC additive maintains transparency of final PVC product

Conduct accelerated weathering tests on impact-modified PVC to assess how additives affect the material's weatherability and mech. Properties

Measure the particle size of the acrylic emulsion at each stage of processing: from seed to core to final stage to ensure it is within 10nm of limit

Lab-Scale Experimentation

Lab-scale version - 4kL acrylic emulsion reactor which mimics the overall process and feeding of monomers

Lab-scale version of spray-drier that helps conduct each experiment to analyse the final powder properties of PVC additives

Prepare the mixture of PVC resin with the necessary PVC additives according to compound formulation

Lab-scale version - 4kL acrylic emulsion reactor which mimics the overall process and feeding of monomers

Lab-scale version of spray-drier that helps conduct each experiment to analyse the final powder properties of PVC additives

Prepare the mixture of PVC resin with the necessary PVC additives according to compound formulation

Application Testing

Prepare samples of PVC sheets based on customized formulations to test transparency, color, lubrication properties of PVC additives

Measure the tensile strength of PVC sample according to ASTM D638 to determine the maximum stress sample can withstand before breaking.

Prepare samples of PVC sheets based on customized formulations to test transparency, color, lubrication properties of PVC additives

Measure the tensile strength of PVC sample according to ASTM D638 to determine the maximum stress sample can withstand before breaking.

Combine several PVC sheets by melting sheets under heat and pressure, resulting in rectangular specimens that can be used for further testing e.g., Izod impact strength create specimens for conducting further

Measure the Izod impact strength of PVC sample according to ASTM D256 to determine the impact resistance using a notched specimen and a pendulum impact tester

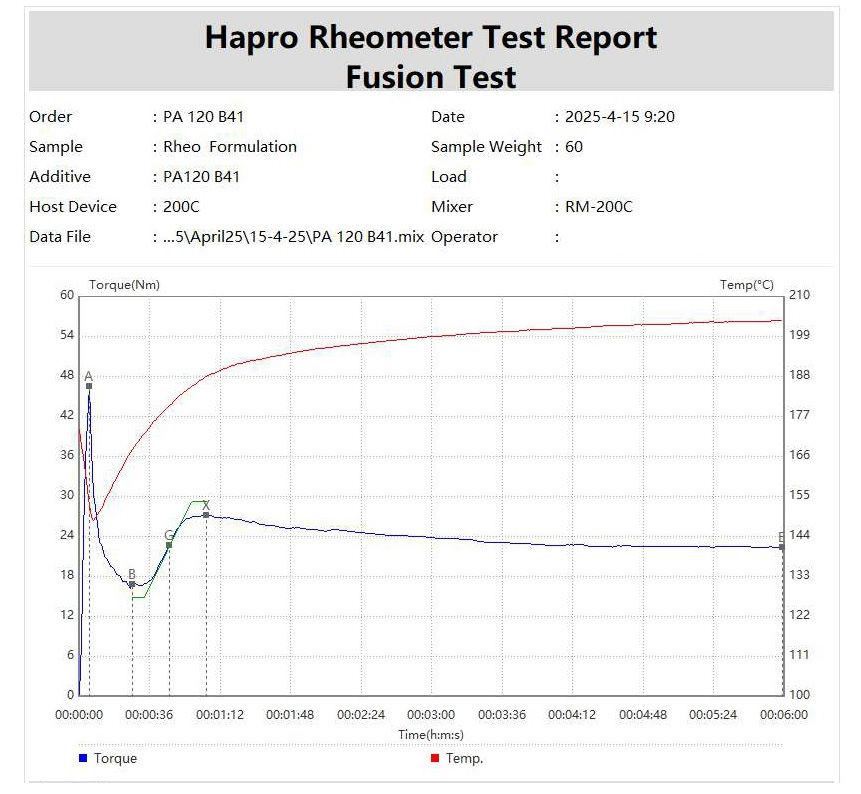

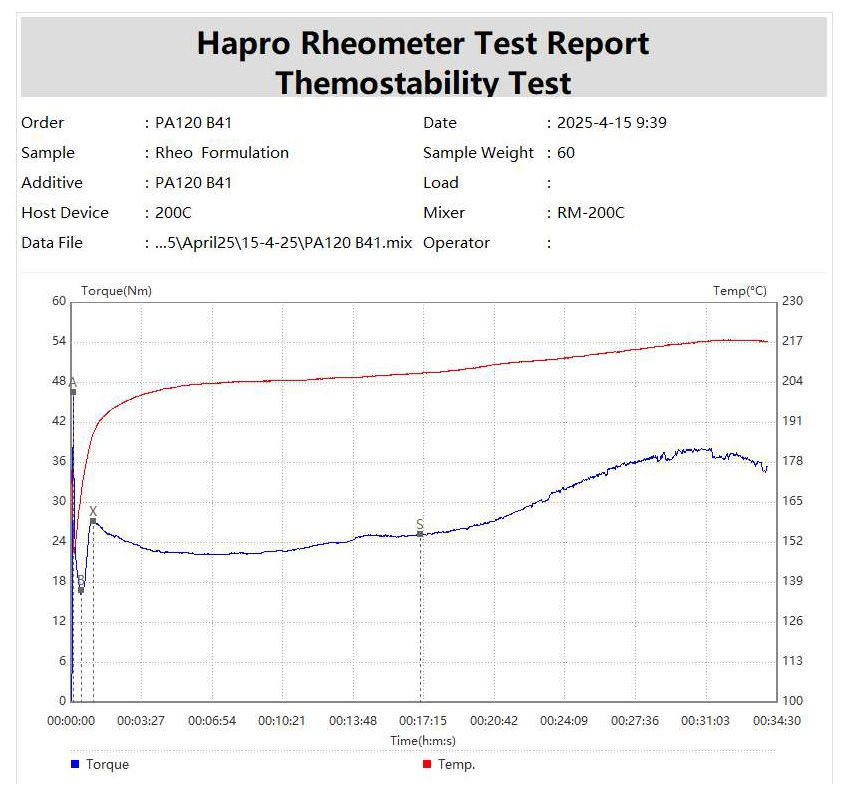

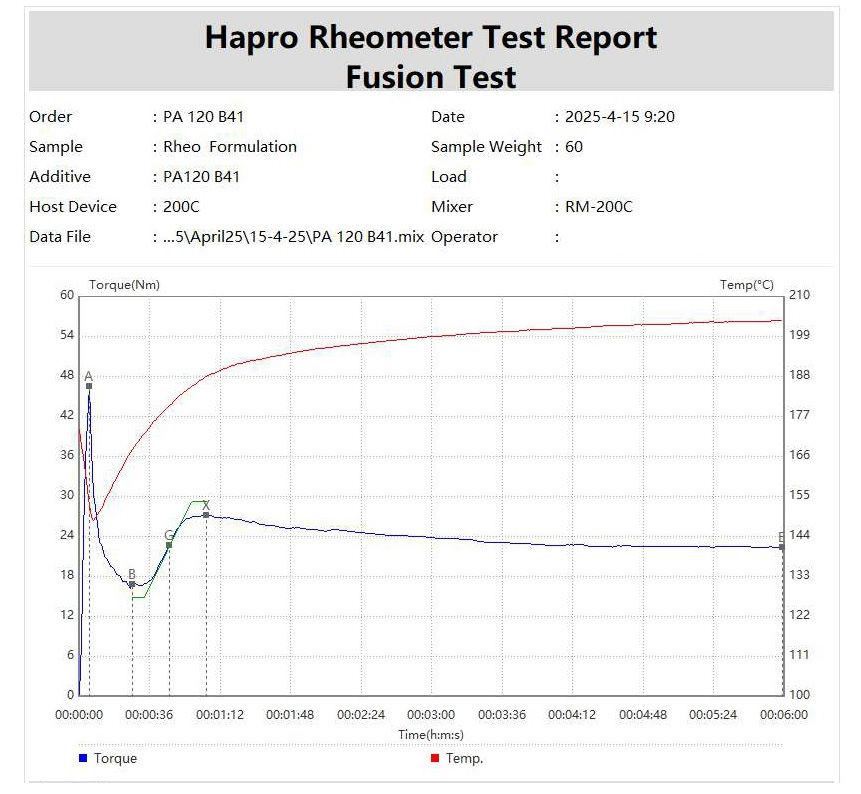

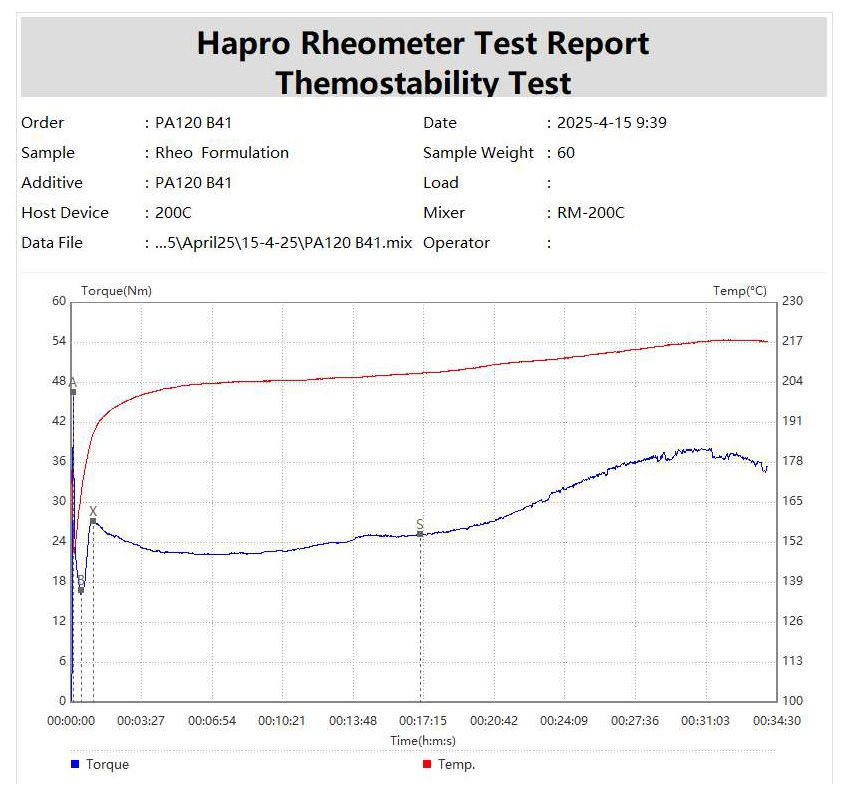

Measure the rheological properties of materials. It measures the torque (rotational force) required to rotate a sample at controlled rate

Conduct the fusion test - Evaluates the fusion characteristics of PVC compounds, including fusion time, fusion torque and melt torque

Conduct the thermostability test - Assess the thermal stability of PVC compounds, which is crucial for understanding their degradation behavior

Combine several PVC sheets by melting sheets under heat and pressure, resulting in rectangular specimens that can be used for further testing e.g., Izod impact strength create specimens for conducting further

Measure the Izod impact strength of PVC sample according to ASTM D256 to determine the impact resistance using a notched specimen and a pendulum impact tester

Measure the rheological properties of materials. It measures the torque (rotational force) required to rotate a sample at controlled rate

Conduct the fusion test - Evaluates the fusion characteristics of PVC compounds, including fusion time, fusion torque and melt torque

Conduct the thermostability test - Assess the thermal stability of PVC compounds, which is crucial for understanding their degradation behavior